#Direct Drive 3D Printer

Explore tagged Tumblr posts

Text

This project might be what breaks my 'don't put behind a paywall' policy. Depends on if I can cover materials and shipping without breaking the bank. Both mine and prospective customers.

Shipping outside the US might not be possible.

If I can't deliver at all, or to a large enough capacity? (I only have one working machine). Then, a free model release on thingiverse is certain. From there, all you need is a direct drive 3D printer and some easy-to-source materials.

It's already more than scribbles. Here's a prototype (springless):

16 notes

·

View notes

Text

the stars team were a group of “handlers and r&d in training” with them starting when they were 15 in the hope of getting a better life, you’d think this means they have some tragic backstory…

They don’t really have one? They grew up on earth to middle income families in the same small nowhere town, watching all these cool mech battles on tv, reading about how to build and take them apart during their formative years, they dreamed not to actually pilot any of the machines into combat, but to make their name like the famous engineers of the past, they need a weapons platform that will be used for over a hundred years after they all die, a weapon so unique that it will start a revolution in the industry at large

So the solution was simple, they all signed up to be “apprentice handlers and assistants in development” for a defense company, you think “oh so they had direct interaction with the pilots and helped with the minor parts of the gun” no, they got to sweep the floors of the building and learn how to press buttons on the industrial 3d printer, “go grab this amount of food for me and my pilot before we go out on sortie" and “go place our order for some burgers and chips from the local fast food store, we’re close to a breakthrough and you lack the clearance to watch anyway”

days became weeks and weeks became months of the same monotonous bullshit, theres development and things yes, they are learning yes, but at this point their talents are being used for little little more than gophering and mechanical work, they’re learning more about trade and stocks than they are about the weapons they actually want to make, then an opportunity arises.

“volunteers wanted” the sign said “go to the planet of akron and help the pilots survive for more than 6 months and you will receive over 50x you’re current pay” that amount of money could get them A LOT of tools that THEY OWN and with the notoriety of such a feat they could gain funding from the many people similar to them in this business, while the planet has a low survival rate they don’t even have to fight personally, that’s what the TWENTY NINE pilots also coming are for, they’ve see the reports on them as well, hundreds of mechs have been bested by these teams, and they get to study their mechs without any backseat driving from their higher ups.

and so they took the devils deal, and hoped they wouldn’t regret it

6 notes

·

View notes

Text

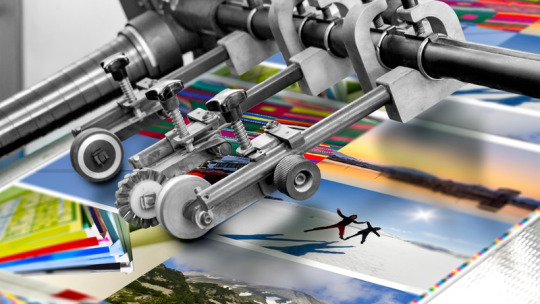

What is the Demand for the Printing Industry?

The printing industry has undergone a profound transformation in recent years, adapting to the challenges and opportunities presented by the digital age. Once considered a traditional and stable sector,

the printing industry is now a dynamic field shaped by technological advancements, changing consumer behaviors, and evolving market demands. This article explores the current state of the printing industry, delving into the demand factors that drive its growth and adaptation.

I. Historical Perspective:

To understand the current demand for the printing industry, it is essential to trace its historical evolution. Traditionally, printing was dominated by analog processes, including letterpress and offset printing. These methods were instrumental in disseminating information through newspapers, magazines, and books. However, the advent of digital technologies, particularly the internet, marked a paradigm shift in communication and information dissemination.

II. Technological Advancements:

a. Digital Printing: The rise of digital printing technologies has been a game-changer for the industry. Digital printing allows for shorter print runs, variable data printing, and quicker turnaround times. This flexibility has made it more cost-effective for businesses to produce personalized and on-demand print materials, catering to niche markets and individualized consumer preferences.

b. 3D Printing: In recent years, 3D printing has emerged as a revolutionary technology with implications across various industries. While not traditionally associated with the printing sector, 3D printing enables the production of three-dimensional objects layer by layer. This technology has found applications in prototyping, manufacturing, healthcare, and even construction, expanding the horizons of the printing industry.

III. Market Trends and Dynamics:

a. Packaging: The demand for printed packaging has witnessed substantial growth, driven by the e-commerce boom and the increasing need for visually appealing product packaging. Printers play a crucial role in creating eye-catching labels, boxes, and packaging materials that enhance brand visibility and influence consumer purchasing decisions.

b. Sustainable Printing: Environmental concerns have become a significant factor influencing consumer behavior and corporate practices. The printing industry has responded by embracing sustainable practices, including the use of eco-friendly inks, recycled paper, and energy-efficient printing processes. Sustainable printing has become a key selling point for businesses aiming to reduce their ecological footprint.

c. Personalization: Consumers today seek personalized experiences in all aspects of their lives, including print materials. The printing industry has capitalized on this trend by offering customized products, such as personalized books, calendars, and promotional materials. Variable data printing allows for the incorporation of individualized content, addressing the growing demand for unique and tailored printed items.

IV. Print vs. Digital: Finding the Balance

a. Coexistence of Print and Digital: While digital technologies have transformed communication, print media has not become obsolete. Instead, there is a growing recognition of the complementary roles played by print and digital formats. Print materials offer a tangible and tactile experience that digital content cannot replicate. Businesses and marketers are increasingly adopting integrated strategies that leverage both print and digital channels to reach a broader audience.

b. Print in the Digital Marketing Mix: Printed materials continue to hold a significant place in marketing strategies. Direct mail, brochures, and promotional materials remain effective in conveying a brand’s message and establishing a physical connection with consumers. The unique qualities of print, such as texture and color depth, contribute to creating memorable and impactful marketing collateral.

V. Challenges and Opportunities:

a. Economic Factors: The printing industry is not immune to economic fluctuations. Economic downturns can lead to reduced advertising budgets, impacting the demand for printed marketing materials. On the other hand, economic recovery and growth can stimulate business activities, prompting increased investment in print advertising and promotional campaigns.

b. Digital Competition: The rise of digital alternatives poses a challenge to the printing industry. Online platforms, social media, and digital advertising offer cost-effective and highly targeted ways to reach audiences. Printers must adapt by offering unique value propositions, such as high-quality printing, specialty finishes, and personalized services that differentiate them from digital alternatives.

c. Technological Disruption: While technological advancements present opportunities, they also pose challenges for traditional printing methods. As 3D printing and digital technologies continue to evolve, printers must invest in updating their equipment and skills to stay competitive. Embracing automation and artificial intelligence in print workflows can enhance efficiency and reduce costs.

VI. Future Outlook:

a. 3D Printing’s Role: The integration of 3D printing into mainstream manufacturing processes is expected to reshape the printing industry further. From producing prototypes to creating custom products on-demand, 3D printing holds the potential to revolutionize the way goods are designed and manufactured.

b. Augmented Reality (AR) and Print: Augmented Reality has the potential to merge the physical and digital worlds, offering interactive and immersive experiences. Print materials augmented with AR can provide additional layers of information, making them more engaging for consumers. This integration may open new avenues for creativity and innovation in the printing industry.

c. Continued Emphasis on Sustainability: As environmental concerns continue to gain prominence, the printing industry’s commitment to sustainability is likely to grow. Printers may increasingly adopt eco-friendly practices, and consumers may show a preference for products with environmentally conscious printing processes.

Conclusion:

The printing industry‘s demand is intricately tied to technological advancements, market trends, and evolving consumer preferences. While challenges persist, the industry has demonstrated resilience by embracing innovation and adapting to changing dynamics.

As we move forward, the coexistence of traditional and digital printing methods, coupled with a commitment to sustainability and personalized experiences, will shape the future of the printing industry. The key lies in finding the right balance between technological innovation and timeless print qualities to meet the diverse demands of a rapidly evolving landscape.

#3d printing#3d sign#3d signage#signage#branding#poster#printing company#print on demand services#print on demand#digital art#pod#print on demand company#print on demand in India

3 notes

·

View notes

Text

3D Printing Industry Growth Fueled by Customization and Manufacturing Efficiency

The 3D Printing Market is on a Strong Upward Trajectory

The global 3D printing market is witnessing remarkable momentum as adoption increases across industries such as aerospace, healthcare, automotive, and consumer goods. As companies shift toward agile, cost-effective manufacturing, the demand for 3D printing solutions is accelerating. According to Mordor Intelligence, the market is projected to grow at a CAGR of 22.66% during the forecast period, driven by increasing investments, technological advancements, and the shift to mass customization.

Market Overview

The 3D printing industry market size is expanding rapidly, with both industrial and desktop 3D printers seeing increased demand. Manufacturers are leveraging this technology for prototyping, tooling, and increasingly, direct production. The use of 3D printing services is also growing as more companies opt for external expertise rather than investing in in-house capabilities. This has further fueled the growth of the 3D printing services market.

From small startups to Fortune 500 companies, businesses are adopting 3D printing to streamline supply chains, reduce waste, and bring products to market faster. The affordability of printers and materials, along with the rise of user-friendly design software, continues to lower the barrier for entry.

Key Trends Driving the 3D Printing Market

Shift Toward End-Use Production The technology is moving beyond prototyping. More companies now use 3D printing for actual product manufacturing, particularly in healthcare for prosthetics and dental implants, and in aerospace for lightweight components.

Growth in Metal 3D Printing Demand for metal 3D printing is surging due to its application in critical industries such as aerospace and automotive, where strong, lightweight parts are essential.

Increased Use of 3D Printing Services With the rise of the 3D printing services market, companies without in-house expertise are outsourcing their production needs, making the technology more accessible.

Advancements in Materials and Processes The availability of new materials like bioplastics, high-performance polymers, and composite filaments is broadening the scope of applications across industries.

Integration with AI and Automation AI-driven optimization and automated post-processing solutions are being integrated to improve the efficiency and accuracy of 3D printing operations.

Challenges in the 3D Printing Industry

Despite strong 3D printing market growth, several challenges remain. High initial setup costs for industrial-scale printing can be a barrier for small and medium enterprises. Intellectual property concerns also arise with the ease of replicating designs. Additionally, inconsistent regulatory standards across regions limit the use of 3D printed parts in safety-critical applications such as medical and aerospace components.

Another ongoing issue is the limited speed and scalability of some 3D printing methods, which prevents their use in high-volume production environments.

Conclusion

The 3D printing market size is set for exponential growth as innovation continues to drive down costs and expand capabilities. With a projected CAGR of 22.66%, the technology is poised to redefine how products are designed, manufactured, and distributed. While challenges remain, the market is being shaped by trends such as end-use production, expanding material options, and AI integration. Businesses aiming to stay competitive should closely follow 3D printing market trends and consider how to strategically adopt or integrate this transformative technology into their operations.

Other Related Reports:

Anti-counterfeit Packaging Market

Telecom Cloud Market

Chiller Market

Paper Straw Market

#3d printing industry growth#3d printing industry market size#3d printing market#3d printing market growth#3d printing market research#3d printing market share#3d printing market size#3d printing market trends#3d printing services market

0 notes

Text

Durable and Accurate Prints with High-Quality 3D Printing Resin

Achieve flawless surfaces and fine detail with cutting-edge 3D Resin. Preferred across industries for its precision and consistent performance.

Modern manufacturing demands precision, durability, and innovation. Engineers, designers, and developers across the globe are constantly searching for the right material to bring digital designs into the physical world without compromising on quality. For industries looking to take their additive manufacturing capabilities to the next level, advanced 3D Printing resin has become an essential material. This resin offers the ideal combination of strength, flexibility, and resolution—making it indispensable for professional-grade 3D printing tasks.

At the core of this innovation lies Jyoticeramic , a brand known for engineering materials with exceptional performance in mind. The JYOCURE resin range is specifically developed for high-resolution stereolithography (SLA) and digital light processing (DLP) printers. This resin meets the needs of professionals who prioritize smooth finishes, detailed accuracy, and reliable outcomes in every print.

Resin printing has outpaced traditional methods in many sectors because of its ability to replicate even the smallest design elements. From functional parts to intricate concept models, 3D printing has revolutionized rapid prototyping. What sets apart high-grade resins is their post-cure durability and low warping properties—factors that are fully addressed in this modern printing material.

JYOCURE by jyoticeramic : Performance You Can Trust Engineered for industrial-grade performance, JYOCURE resin meets the demands of high-resolution 3D printing applications. It is designed to reduce shrinkage and eliminate layer misalignment during both the printing and curing processes. This resin adapts seamlessly across various sectors such as automotive, aerospace, dental, and consumer electronics, offering reliability and efficiency for professionals working in diverse printing environments.

Key Benefits of the Resin:

Excellent tensile strength ensures structural integrity

High-definition output on intricate geometries

Smooth, matte finish suitable for direct use

Reduced post-processing shrinkage

UV resistance and extended shelf life

Its robust formulation supports a wide range of printing systems, providing flexibility and consistent results.

Industrial Applications Driving Change The adaptability of this has made it a popular choice beyond conventional prototyping. Professionals use it to craft functional master molds, precise mechanical parts, and visually accurate mockups. Its role in medical modeling provides realistic anatomical structures beneficial for educational and surgical use.

With clear visual output and high thermal endurance, the resin is suitable for translucent enclosures and parts exposed to environmental stress. Its reliable mechanical properties make it ideal for rigorous product testing, both functional and aesthetic.

Professionals High-Performance Resin Automotive researchers benefit from this resin's ability to replicate detailed curves and fine textures directly from CAD models. This reduces development time and enhances prototype accuracy. Automotive parts printed with this material are visually polished and capable of fit and function testing, which improves team collaboration and speeds up design validation.

Engineers value this resin for consistent performance without requiring frequent recalibration. It enables complex design execution while maintaining fast iteration speeds. From mechanical assemblies to presentation-ready models, the resin supports innovation and efficiency in every stage of product development.

Design Studios Using 3D Resin for Client Mockups Design and marketing agencies rely on presentation-quality outputs. This resin accurately replicates engraved text, fine edges, and layered detail, helping creators deliver samples that match the original concept. It elevates customer interaction and supports faster decision-making.

Architects and consumer brands use this material to create scaled models that are not only visually compelling but also durable enough for handling. The tactile feedback enhances client satisfaction and makes concept validation smoother.

Educational Use and Innovation Hubs Academic institutions and tech labs are leveraging this advanced resin to support hands-on learning. It is widely used in fields ranging from biology to electronics. From visual teaching aids to circuit housing prototypes, the resin facilitates affordable and accessible digital fabrication.

Its compatibility with standard SLA systems makes it ideal for institutions aiming to improve their technical infrastructure without significant investments.

Applications Include:

Prototyping for automotive and aerospace industries

Dental and anatomical modeling

Jewelry and precision mold casting

Engineering and industrial design mockups

Educational and research-based fabrication

This versatile material transforms ideas into high-quality physical prototypes effortlessly.

Choose a trusted 3D Printing Resin for creating reliable prototypes and end-use parts. It empowers innovation through accuracy, speed, and material strength.

Visit: https://www.jyoticeramic.com/jyocure.php

Contact: +91 253 6918111

0 notes

Text

3D Scanning Market Set to Record Exponential Growth by 2030

Allied Market Research, titled, “3D Scanning Market Size By Type, Services, Range, and Application: Global Opportunity Analysis and Industry Forecast, 2021–2030”, The 3D scanning market size was valued at $3.72 billion in 2020, and is projected to reach at $16.66 billion by 2030, growing at a CAGR of 16.3% from 2021 to 2030.

3D scanning technology is an improved process of analyzing an environment in the real world by collecting data in order to recreate a three-dimensional shape and appearance. Moreover, 3D laser scanner is well suited to the measuring & inspection of curved surfaces and complicated geometries that require enormous volumes of data with the correct description. The 3D scanning market has witnessed significant development, owing to the high adoption of AR/VR devices and the commercialization of autonomous vehicles.

The global 3D scanning market trends are majorly driven by increase in need to capture large volumes of 3D data for modelling and analysis paired with surge in need for highly accurate 3D scanning. Moreover, ongoing technological advancements in 3D scanning is anticipated to drive the growth of 3D scanning. However, dependence of market growth on non-3D businesses and high price of high-resolution 3D scanners are acting as a prime restraint of the market. On the contrary, structured light-based 3D scanning and growing 3D printing market generating demand is anticipated to provide lucrative opportunities for the 3D scanning industry during the forecast period.

According to 3D scanning market analysis, the laser scanner segment was the highest contributor to the market in 2020. The short range scanning and long-range scanner segments collectively accounted for around 81.9% market share in 2020. Surge in adoption of VR and AR solution led the growth of the medium range scanning and long range scanner segment, thereby, enhancing the 3D scanning market growth.

The outbreak of the COVID-19 has significantly impacted the growth of the 3D scanner and 3D printer scanner application. Decline in demand for applications such as projectors has significantly impacted the demand for 3D scanning solutions during the pandemic. Further, lack of availability of a professional workforce due to partial and complete lockdown implemented by governments across the globe has restrained the growth of the 3D scanning market during a pandemic. However, rise in demand for VR and digital application-based gaming solution has led the growth of three-dimensional scanning solutions that is expected to drive the growth of the market after pandemic.

Region-wise, Asia-Pacific holds a significant share in the global 3D scanning market, owing to the presence of prime players in this region. Further, China holds a dominating position in the market, owing to rise in investment by prime players and government agencies to develop next generation 3D scanning solution. The adoption of 3D printing solution across healthcare, construction, and other sectors is expected to propel the growth of the 3D scanning industry in this region.

Key Findings of the Study

In 2020, the laser scanner segment accounted for maximum revenue, and is projected to grow at a notable CAGR of 16.7% during the forecast period.

The short range scanning and long range scanner segments together accounted for around 81.9% of the market share in 2020.

The healthcare segment is projected to grow at a CAGR of 20.0% during the forecast period.

North America contributed for the major share in the market, accounting for more than 40.3% share in 2020.

The key players profiled in the report include Faro Technologies Inc., Creaform Inc., Direct Dimensions Inc., GOM GmbH, Konica Minolta Inc., Nikon Corporation, Autodesk Inc., 3D Systems Inc., ShapeGrabber, and Maptek Pty Ltd. These market players have adopted various strategies, such as product launch, collaboration & partnership, joint venture, and acquisition, to expand their foothold in the industry.

0 notes

Text

Building with Polypropylene: Applications and End-Use Industries in European 3D Printing

The Europe polypropylene in 3D printing market size is expected to reach USD 4,084.44 thousand by 2030. The market is expected to expand at a CAGR of 15.2% from 2022 to 2030. The regional market is expected to register growth due to the high adoption of polymers in implants, on account of their abrasion resistance, chemical resistance, and durability. The demand for electric vehicles and the growing utilization of high-performance and lightweight plastic components by many manufacturers is further expected to drive the polypropylene in 3D printing market growth in Europe.

In addition, the high level of consumer expenditure on healthcare, primarily in Germany, is expected to drive the filament form segment. France has witnessed advancements in terms of technology across its aerospace & defense industry. 3D hubs, 3D Ceram, 3D Prod, and 3D Ceram SAS are some of the companies that integrate 3D printing, creating opportunities for 3D printed polypropylene.

End-use industry players in Europe are investing heavily in developing 3D printing technologies which can fuel the market for polypropylene in 3D printing. For instance, in June 2021, Volkswagen AG announced the use of a new 3D printing process in vehicle production. The company will use binder jetting, a 3D printing technology, to manufacture components at the company’s main plant in Wolfsburg, Germany.

Major players are entering into partnerships to develop additional 3D printing powders. In November 2021, Covestro AG and Farsoon announced the extension of their partnership of polymer 3D printing materials. The companies have strengthened their collaboration by announcing additional 3D printing powders. Covestro has already launched Thermoplastic Polyurethane (TPU) and Polybutylene Terephthalate (PBT) powders using the latter’s machines and now plans for additional powders.

In January 2022, a group of organizations from Canada and Germany, including Fraunhofer Institute for Laser Technology (ILT), BCT, National Research Council of Canada (NRC), McGill University, and Apollo Machine & Welding Ltd., set up a new project named Artificial Intelligence Enhancement of Process Sensing for Adaptive Laser Additive Manufacturing (AI-SLAM). This was done to automate the process of repairing parts using artificial intelligence and 3D printing. The project is aimed to develop advanced AI-based software to run Directed Energy Deposition (DED) 3D printers.

Europe Polypropylene In 3D Printing Market Report Highlights

In terms of revenue, the filament segment accounted for a prominent share in the market in 2021 and is further expected to witness notable growth during the forecast period

The automotive industry dominated the regional market and accounted for more than 32.0% of the revenue share in 2021, owing to the lightweight, high bacterial and chemical resistance properties provided by the polypropylene

As of 2021, Germany accounted for more than 24% of the revenue share in the overall market, due to increasing utilization of high-performance lightweight plastic components by many manufacturers to achieve fuel efficiency and weight reduction in passenger as well as sports cars in the region

End-use companies are entering into strategic partnerships with polypropylene manufacturers to develop customized materials for their products and gain a competitive advantage

In April 2020, BASF SE and H.P. Development Company, L.P. partnered to create a new 3D printing polypropylene (P.P.) material that delivers high productivity and minimizes waste for industrial-level manufacturing. This polypropylene material can be used to prototype and produce parts, including vehicles’ exteriors, interiors, and under the hood

In December 2020, LyondellBasell Industries Holdings B.V. launched Beon3D, a polypropylene compound having good surface quality, high dimensional stability, and good heat resistance, enabling it to be used in the manufacturing of complex and high-quality parts in 3D printing

Get a preview of the latest developments in the Europe Polypropylene In 3D Printing Market? Download your FREE sample PDF copy today and explore key data and trends

Europe Polypropylene In 3D Printing Market Segmentation

Grand View Research has segmented the Europe polypropylene in 3D printing market based on form, end-use, and country:

Europe Polypropylene in 3D Printings Market Outlook, By Form (Volume, Kilotons; Revenue, USD Thousand, 2019 - 2030)

Filament

Powder

Europe Polypropylene in 3D Printings Market Outlook, By End-Use (Volume, Kilotons; Revenue, USD Thousand, 2019 - 2030)

Automotive

Medical

Aerospace & Defense

Consumer Goods

Europe Polypropylene in 3D Printings Regional Outlook (Volume, Kilotons; Revenue, USD Thousand, 2019 - 2030)

Europe

UK

Germany

France

Italy

Czech Republic

Poland

Hungary

Romania

Key Players in the Europe Polypropylene In 3D Printing Market

BASF SE

LyondellBasell Industries Holding B.V.

SABIC

Exxon Mobil Corporation

Covestro AG

RECERUS INDUSTRIES S.L.

Braskem

Sculpteo

Order a free sample PDF of the Europe Polypropylene In 3D Printing Market Intelligence Study, published by Grand View Research.

0 notes

Text

Choosing the Right E3D Products for Your Printing Needs

Introduction

E3D is a major producer known for its superior technology and unique solutions. Whether you are a novice or a professional, knowing which E3D products are best for your printing needs will greatly improve your 3D printing experience. This guide will help you browse E3D's many offerings and make informed judgments.

Understanding E3D products

E3D is well-known for manufacturing high-performance hotends, nozzles, extruders, and other key 3D printing components. Each product is meticulously developed to provide long-lasting performance and consistency. Whether you want to modify an existing printer or construct one from the start, E3D offers a variety of solutions adapted to your specific requirements. Their goods are compatible with a variety of 3D printer types, making them a popular choice for both enthusiasts and professionals.

Selecting the Right E3D Hotend

The hotend is a fundamental component in 3D printing. E3D has numerous possibilities, such as the V6, Revo, and Volcano series. The V6 hotend is appropriate for conventional printing activities since it can operate at high temperatures and is versatile. The Volcano hotend's enhanced flow rate makes it a good alternative for faster and larger prints. Meanwhile, the Revo series is ideal for individuals who want to replace nozzles quickly and easily without the use of sophisticated tools. Identifying your printing needs can help you choose the best E3D hotend for your projects.

Exploring E-3D Nozzles

Nozzles have an important role in influencing print quality and speed. E3D provides a range of nozzles made of brass, stainless steel, and toughened steel. Brass nozzles are good for general-purpose printing, whereas stainless steel nozzles are suitable for food-safe and medical applications. Hardened steel nozzles are ideal for use with abrasive materials such as carbon fiber or glow-in-the-dark filament. Choosing the proper nozzle ensures that your E3D system performs well and lasts as long as possible.

E3D extruders and accessories

Extruders feed filament into the hotend, and E3D provides both direct drive and Bowden extruders. The Hemera extruder is a popular direct drive alternative that offers accurate filament management for both flexible and conventional materials. Bowden extruders, on the other hand, are lightweight and ideal for quick prints that place less strain on the moving components. E3D also provides crucial components such as temperature sensors, heater blocks, and cooling systems to help your printer run smoothly.

Conclusion

Choosing the proper E3D goods is critical for producing high-quality 3D prints and optimizing your printing experience. Understanding the various hotends, nozzles, and extruders available allows you to choose the components that best suit your requirements. E3D's commitment to innovation and quality ensures that you have access to dependable and efficient goods for all of your 3D printing needs. Invest in E3D items to improve your printing capabilities and achieve exceptional outcomes.

0 notes

Text

3D Printing Stainless Steel Market Analysis of Emerging Trends Opportunities and Challenges with Strategic Insights for Long-Term Growth Outlook

The 3D printing stainless steel market is experiencing rapid evolution, with emerging trends, opportunities, and challenges shaping its long-term growth outlook. This technology, which enables the creation of intricate, durable, and customized stainless steel components, is being adopted across a variety of sectors, including aerospace, automotive, healthcare, and manufacturing. As the market matures, strategic insights into key developments will be essential for understanding its potential for sustained growth.

Emerging Trends

One of the most significant emerging trends in the 3D printing stainless steel market is the increasing use of this technology for producing highly customized parts. Traditional manufacturing techniques often struggle to meet the demand for low-volume, specialized components, but 3D printing excels in this area. In industries such as healthcare, 3D printed stainless steel implants and prosthetics can be tailored to individual patient needs, offering improved performance and faster recovery times. Similarly, aerospace and automotive sectors benefit from the ability to produce lightweight, high-strength parts with complex geometries that would be difficult or impossible to achieve using conventional methods.

Another emerging trend is the growing emphasis on sustainability. Traditional manufacturing processes, especially in industries like aerospace and automotive, are resource-intensive and contribute to significant material waste. 3D printing offers a more sustainable alternative, using only the required amount of material and reducing waste. Furthermore, many 3D printing technologies allow for the recycling of metal powders, further enhancing their eco-friendliness. This trend aligns with the broader push toward sustainable production practices and is expected to drive further adoption of 3D printing stainless steel.

Opportunities for Growth

The opportunities for growth in the 3D printing stainless steel market are vast, particularly as new alloys and printing techniques are developed. Advances in high-performance stainless steel alloys designed for additive manufacturing are expanding the range of potential applications for 3D printing. These alloys offer enhanced properties such as improved strength, corrosion resistance, and thermal stability, making them suitable for even more demanding industries, including energy and defense.

Additionally, the ongoing development of 3D printing technologies is unlocking new opportunities for more efficient production processes. Techniques like direct energy deposition (DED) and selective laser melting (SLM) are continually improving, enabling faster production times, higher precision, and better part quality. These innovations not only enhance the performance of 3D printed stainless steel components but also make the technology more cost-effective, driving its adoption across industries that previously relied on traditional manufacturing methods.

Challenges to Overcome

Despite its promising potential, the 3D printing stainless steel market faces several challenges that could impact its long-term growth. One of the primary obstacles is the high cost of 3D printing equipment and materials. While the technology has become more accessible in recent years, the initial investment required for 3D printers capable of handling stainless steel remains significant. Additionally, the cost of metal powders used in 3D printing can be prohibitive for some smaller manufacturers, limiting their ability to capitalize on the technology.

Another challenge is the limited availability of skilled labor. Although 3D printing technology is becoming more widespread, it requires specialized knowledge and expertise to operate effectively. Companies seeking to implement 3D printing on a larger scale must invest in training and workforce development to ensure they can maximize the potential of this technology.

Strategic Insights for Long-Term Growth

To ensure long-term growth in the 3D printing stainless steel market, companies should focus on the following strategic areas:

Material Innovation: Continued research into new alloys and composite materials that can enhance the performance of 3D printed stainless steel will be crucial for expanding the range of applications and improving cost-efficiency.

Collaboration and Partnerships: Building partnerships between 3D printer manufacturers, material suppliers, and end-users will foster innovation and enable the development of optimized solutions for various industries.

Process Optimization: Investing in the development of faster, more efficient 3D printing technologies will help drive down costs and increase adoption, particularly for industries where time and cost are critical factors.

Workforce Development: To overcome the skill gap, companies should invest in training programs that develop the necessary expertise in 3D printing and additive manufacturing, ensuring they can capitalize on the potential of the technology.

In conclusion, while the 3D printing stainless steel market faces challenges, its growth potential remains significant. By focusing on material innovation, collaboration, and process optimization, companies can position themselves for success in a rapidly evolving market, ensuring sustainable growth in the years to come.

Request Sample PDF Market: https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NjE5&RD=3D-Printing-Stainless-Steel-Market-Report

#3DPrintingStainlessSteelMarket#3DPrintingStainlessSteelMarketTrends#3DPrintingStainlessSteelMarketInsights#3DPrintingStainlessSteelMarketGrowth#3DPrintingStainlessSteelMarketForecast#3DPrintingStainlessSteelMarketOpportunities

0 notes

Text

So, uh, Tumblr recommended this post to me and boy howdy. "Blogs like ... my own are probably traps". Ya don't say.

The everything above is stupid. If you are over 18, have nothing in your background, and $250 you can buy a gun. In many states there isn't a waiting period. Or state ownership lists. If you have a little bit of steel in your spine, a friend of questionable other friends, and $300 you can buy a gun on the street. If you have a gun owning friend who is looking to get rid of a gun you can buy direct from them. There are many states where getting a gun is easier than getting a state ID. Many, many guns are cheaper than a 3D printer. Many libraries will print whatever little bauble you ask them to for the cost of supplies and pennies on the hour. And many larger metropolitan areas have multiple library branches with 3D printers.

If we have a war, it probably isn't gonna be with China. Do you know how much money our CEOs make from China? Do you know how much we import from them? Good luck buying a car or computer or crayfish if China cuts us off. We are not going to war with China. I mean, we are openly going to war with what is left of Palestine. There's a whole Middle East and Africa that the incoming Administration openly would love to carpet bomb and it wouldn't impact the oligarchy's money train much at all. I mean, we already attack them to enforce our supply chains and none of them are large enough to kick us out, which China is.

So, remember: "If they'll drive you to the criming they're a fed."

And if they post something so mind numbingly stupid as to presume that the only way most people can legally get a gun involves the internet, which saves you neither time nor money nor bypasses state laws, they're a bot and you should block them.

1 note

·

View note

Text

Understanding Electric Motors: Types, Applications, and Benefits

Electric motors are integral to modern technology, powering everything from household appliances to industrial machinery and electric vehicles. These versatile devices convert electrical energy into mechanical energy, enabling motion and functionality in countless applications. Understanding the types, applications, and benefits of electric motors is essential for both professionals and consumers looking to make informed decisions about their use.

What is an Electric Motor?

An electric motor is a machine that converts electrical energy into mechanical energy through electromagnetic interactions. The basic principle of operation involves generating rotational motion when an electric current passes through coils within a magnetic field. This mechanical energy is then used to drive various devices and systems.

Types of Electric Motors

Electric Motors are categorized based on their design, power source, and intended application. Here are the primary types:

1. AC Motors

AC (Alternating Current) motors are powered by alternating current and are commonly used in applications requiring consistent speed and efficiency.

Induction Motors: These are widely used due to their durability and low maintenance. They are ideal for industrial and domestic applications, such as fans, pumps, and conveyors.

Synchronous Motors: Operate at a constant speed and are suitable for precision tasks like robotics and clock mechanisms.

2. DC Motors

DC (Direct Current) motors run on direct current and offer precise control over speed and torque.

Brushed Motors: Known for their simplicity and affordability, these motors are often used in small appliances and toys.

Brushless Motors: Offer higher efficiency and longevity due to the absence of brushes, making them popular in electric vehicles and drones.

3. Stepper Motors

Stepper motors are designed for precise positioning and control, often used in printers, 3D printers, and CNC machines. They operate in discrete steps, making them ideal for applications requiring accuracy.

4. Servo Motors

Servo motors are compact, high-performance motors used in robotics, cameras, and industrial automation. They provide accurate control of angular position, speed, and torque.

5. Special-Purpose Motors

These include motors designed for unique applications, such as linear motors, which produce linear motion, and universal motors, which can run on both AC and DC power.

Applications of Electric Motors

Electric motors are ubiquitous, serving a wide range of industries and purposes:

Industrial Machinery: Powering conveyors, compressors, and pumps for manufacturing and production processes.

Transportation: Driving electric vehicles, trains, and airplanes, contributing to the shift towards greener transportation.

Home Appliances: Found in washing machines, refrigerators, air conditioners, and vacuum cleaners.

Healthcare Equipment: Used in medical devices such as MRI machines, ventilators, and electric wheelchairs.

Automation and Robotics: Enabling precise movements in robotic arms, drones, and automated systems.

Benefits of Electric Motors

Electric motors offer numerous advantages, making them indispensable in modern technology:

1. Energy Efficiency

Electric motors are highly efficient in converting electrical energy into mechanical energy. Advances in motor design have further enhanced their energy-saving capabilities.

2. Eco-Friendly Operation

Compared to combustion engines, electric motors produce zero emissions during operation, making them a sustainable choice for reducing carbon footprints.

3. Versatility

Available in a wide range of sizes and specifications, electric motors can be tailored to meet specific requirements in diverse applications.

4. Durability and Reliability

With fewer moving parts and robust construction, electric motors are known for their longevity and dependability.

5. Low Maintenance

Many electric motors, especially brushless and induction types, require minimal maintenance, reducing long-term operational costs.

Challenges and Innovations

While electric motors are efficient and versatile, they face challenges such as energy losses and heat generation. However, ongoing innovations are addressing these issues:

Smart Motors: Equipped with sensors and IoT capabilities for real-time monitoring and optimization.

High-Efficiency Designs: Using advanced materials and designs to reduce energy losses and improve performance.

Integration with Renewable Energy: Electric motors are being adapted to work seamlessly with renewable energy sources like wind and solar power.

Conclusion

Electric motors are a cornerstone of modern technology, driving progress across industries and improving everyday life. Understanding the different types, applications, and benefits of electric motors helps individuals and businesses make informed decisions about their use. As innovations continue to enhance efficiency and sustainability, electric motors will remain at the forefront of technological advancement, shaping a greener and more efficient future.

0 notes

Text

Design features and selection principles of linear stepper motors

1.Working principle of linear stepper motors The working principle of linear stepper motors is to drive the slider to move along a straight line through an electromagnetic field. Its basic structure includes a stator and a mover. The stator is usually composed of two electromagnets, and the mover is composed of a slider with a permanent magnet. The working principle is to generate an alternating magnetic field by alternately exciting the electromagnets, which pushes the slider to move along a straight line. When one electromagnet is activated, it generates a magnetic field that attracts the slider and moves toward it; when the other electromagnet is activated, it generates an opposite magnetic field that pushes the slider to move in the opposite direction. By alternately activating these two electromagnets, the slider can reciprocate along a straight line.

2.Common application areas of linear stepper motors 1.Industrial automation: Linear stepper motors are widely used in industrial robots, mold machinery, printing machinery and other equipment, and can provide high-precision, high-stability and high-efficiency motion control. 2.Planar mobile devices: Linear stepper motors are often used in planar mobile devices such as laser cutting machines, printers, scanners, etc., and achieve high-quality processing and printing effects by precisely controlling the movement of the motor. 3.Measuring instruments: In high-precision 3D scanners, optical measuring equipment and other measuring instruments, linear stepper motors are used for precise measurement and positioning to ensure the accuracy of measurement. 4.Medical equipment: Linear stepper motors are widely used in medical equipment such as medical instruments and surgical instruments to drive the movement of scanning frames to ensure accurate imaging of medical imaging equipment. 5.Other applications: Linear stepper motors can also be used in scenes such as focusing of camera lenses and moving optical equipment to provide high-precision position control.

3.Design features of linear stepper motors 1.High precision: Linear stepper motors adopt a direct drive structure, with no backlash and high structural rigidity. The accuracy of the system mainly depends on the position detection element, which can reach the submicron level through a suitable feedback device. 2.No mechanical contact wear: There is no mechanical contact wear between the stator and the mover of the linear stepper motor. The system motion contact is borne by the linear guide rail, with fewer transmission parts, smooth operation, low noise, simple structure, simple maintenance, or even maintenance-free, high reliability and long service life. 3.Modular structure: The stator of the linear stepper motor adopts a modular structure, and the running stroke is theoretically unlimited. 4.Wide operating speed range: The speed range of the linear stepper motor is from a few microns to several meters per second, which can meet different application requirements. 5.High acceleration and speed: In practical applications, the linear stepper motor has achieved an acceleration of 5.5g and a speed of 2.5m/s. 6.High efficiency: Since there is no intermediate transmission link, the energy loss during mechanical friction is eliminated, and the efficiency is high. 7.Fast response speed: Since some mechanical transmission parts with large response time constants, such as lead screws, are eliminated, the dynamic response performance of the entire closed-loop control system is greatly improved, and the response is extremely sensitive and fast. 8.Wide application: Linear stepper motors are mainly used in automatic control systems, long-term continuous operation drive motors, and devices that need to provide huge linear motion energy in a short time.

4.Selection principles of linear stepper motors 1.Load characteristics: Select a suitable motor according to the rotational inertia and friction load of the load. Loads with large moment of inertia should use motors with large frame sizes, while friction loads need to consider static torque, which is usually 2-3 times the friction load. 2.Speed and step angle: The step angle of the stepper motor should be selected according to the load accuracy requirements, and the step angle should be equal to or less than the resolution required by the load. For example, if the positioning accuracy of the load is ±0.5°, the angle rotated by one pulse of the motor should be less than 0.5°. 3.Current parameters: Motors with the same static torque have very different operating characteristics due to different current parameters. The current of the motor can be judged by the torque-frequency characteristic curve. 4.Working environment: Select a suitable stepper motor according to the use environment. For example, for special environments that require waterproofing and oil resistance, special stepper motors should be selected. 5.Application scenarios: Linear stepper motors are generally used in low-speed situations, with a speed not exceeding 1000 revolutions per minute. It is best to control the speed between 1000-3000PPS (0.9 degrees). Appropriate deceleration devices can improve work efficiency and reduce noise.

0 notes

Text

To create a robot shaped like a ball, you’ll need a mix of mechanical, electrical, and software engineering skills, along with some knowledge of robotics. Here’s an overview of the process, broken down into key steps:

1. Conceptual Design

Draw a Blueprint: Use software like AutoCAD, Fusion 360, or SolidWorks to design the robot. Start with its external appearance (the ball) and work inward. Plan where components such as motors, sensors, and power sources will be placed.

Determine Functions: Decide what the robot will do—roll, pick up objects, interact with the environment. This will guide the type of hardware and control mechanisms you’ll need.

2. Materials & Components

Shell: The outer sphere can be made from lightweight but strong materials such as polycarbonate or aluminum. Make sure it can support internal components but is light enough to move.

Motors & Gears: Use DC motors or stepper motors to drive the robot’s movement. Gyroscopic or pendulum mechanisms inside can help with stability and motion.

Gyroscope or Inertial Measurement Unit (IMU): You’ll need this to help with balance and direction control, especially if the robot is meant to roll like a ball (e.g., like the BB-8 from Star Wars).

Wheels/Tracks (Internal): Though the robot will look like a ball from the outside, the movement is usually driven by internal wheels or tracks that keep it balanced as it moves.

Power Source: A rechargeable battery pack will be needed. Choose one that can supply enough power for the motors, sensors, and any external tools (like arms or lights).

Sensors: If your robot will interact with the environment, you might want to include ultrasonic sensors (for obstacle detection), cameras, or IR sensors for remote control.

Microcontroller/Processor: You’ll need a microcontroller to control the robot’s actions, such as an Arduino or Raspberry Pi.

3. Assembly

Chassis Construction: Build the frame inside the ball using 3D printing or metalworking techniques. This frame will hold the internal components securely.

Install Motors and Gyroscopes: Place the motors and gyroscopes in a balanced way to ensure the ball rolls smoothly without tipping over. Align your wheels or internal pendulum system properly.

Mount Sensors: Position sensors where they will be most effective (e.g., ultrasonic sensors at the front to detect obstacles).

Power System: Wire the battery pack to your microcontroller and motors. Use appropriate safety measures to prevent short-circuiting.

4. Programming

Control Code: Write the code that will control the robot’s movements. If using an Arduino, the Arduino IDE can help. For more advanced processing (e.g., object recognition or AI), you may want to use Python or ROS (Robot Operating System) with Raspberry Pi.

Movement Control: Program the gyroscope to keep balance and coordinate with the motors. Implement algorithms to handle acceleration, deceleration, and turns.

Autonomous or Remote-Controlled?: If you want it to be autonomous, you’ll need additional algorithms for obstacle detection and pathfinding. For remote control, integrate Bluetooth, Wi-Fi, or radio controllers.

5. Testing & Debugging

Prototyping: Start with simple tests—ensure it can move and balance properly. Fine-tune motor power and gyroscopic control.

Calibration: Adjust sensors and movement controls to ensure smooth operation. Test it in various environments (smooth floor, rough surfaces) to see how it handles different terrains.

Iterate: You’ll likely go through several iterations of refining components, improving the code, and upgrading hardware.

6. Finishing Touches

Outer Appearance: Once the internals work, focus on the aesthetics. You can paint the shell or add LED lights to give the robot a futuristic look.

Durability: Make sure the ball can withstand collisions or falls, especially if it’s autonomous and will be navigating real-world environments.

Resources You Might Need:

3D Printer: To create custom parts or frames.

Soldering Kit: For wiring and assembling electronics.

Microcontroller Kit: Like Arduino or Raspberry Pi starter kits.

Gyroscope and IMU: Available at electronics stores or online.

Motors and Gears: You can find these on sites like Adafruit or SparkFun.

By following these steps and continuously refining your design, you'll be able to create a working ball-shaped robot!

0 notes

Text

3d Printing Market In-Depth Analysis and Forecast 2024 - 2030

The global 3D printing market size is expected to reach USD 88,281.2 million by 2030, according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 23.5% from 2024 to 2030. 3D Printing (3DP) is also referred to as Additive Manufacturing (AM) as it involves successive addition of layers of materials in various 2D shapes using an additive process. These layered 2D shapes build upon one another to form a three-dimensional object. The process is different from the subtractive method of production, which begins with a block of material and the unnecessary material is ground out to obtain the desired object.

3D printing is widely adopted in the industrial sector owing to the growing need for enhanced product manufacturing and a shorter time to market. The industrial vertical happens to be the most significant adopter of the 3D printing technology, eventually leading to the largest market share of 3D printers for industrial applications over the forecast period. Additive manufacturing is anticipated to evolve over the forecast period.

Gather more insights about the market drivers, restrains and growth of the 3d Printing Market

Detailed Segmentation:

Market Concentration & Characteristics

The 3D Printing Market growth stage is high. The 3D printing market has witnessed a significant degree of innovation, marked by continuous advancements in 3D printing materials market, printing technologies, and the expansion of applications across diverse industries. Ongoing research and development efforts have led to the introduction of more sophisticated and efficient 3D printers, enabling the production of complex and functional objects with improved speed and precision. The dynamic landscape reflects a continuous quest for innovation, with 3D printing increasingly positioned as a transformative technology driving advancements in manufacturing and design processes.

Printer Type Insights

The industrial printer segment led the market and accounted for more than 76.0% share of the global revenue in 2023. Based on the printer type, the industry has been further segmented into industrial and desktop 3D printers. The large share of industrial 3D printers can be attributed to the extensive adoption of industrial printers in heavy industries, such as automotive, electronics, aerospace and defense, and healthcare. Prototyping, designing, and tooling are some of the most common industrial applications across these industry verticals.

Technology Insights

The stereolithography segment led the market and accounted for more than a 10.0% share of the global revenue in 2023. Based on technology, segmentation has been divided into stereolithography, fuse deposition modeling (FDM), direct metal laser sintering (DMLS), selective laser sintering (SLS), inkjet, polyjet, laser metal deposition, electron beam melting (EBM), digital light processing, laminated object manufacturing, and others.

Software Insight

The design software segment led the market and accounted for more than 36% share of the global revenue in 2023. It is expected to continue dominating the market during the forecast period. Based on software, the 3DP industry has been segmented into design software, inspection software, printer software, and scanning software. Design software is used for constructing the designs of the object to be printed, particularly in automotive, aerospace and defense, and construction and engineering verticals. Design software acts as a bridge between the objects to be printed and the printer’s hardware.

Application Insight

The prototyping segment led the market and accounted for more than 54% share of the global revenue in 2023. Based on application, the industry has been segmented further into prototyping, tooling, and functional parts. Prototyping segment accounted for the largest share in 2023 owing to an extensive adoption of the prototyping process across several industry verticals. The automotive, aerospace and defense verticals mainly use prototyping to design and develop parts, components, and complex systems precisely.

Vertical Insight

The automotive segment led the market and accounted for more than 23% share of the global revenue in 2023. Based on vertical, the industry has been segmented into separate verticals for desktop and industrial 3D printing. The verticals considered for desktop 3DP comprise educational purposes, fashion, jewelry, objects, dental, food, and others. The verticals considered for industrial 3DP comprise automotive, aerospace and defense, healthcare, consumer electronics, industrial, power and energy, and others.

Material Insight

The metal segment led the market for 3D printing and accounted for more than 54% share of the global revenue in 2023. Moreover, the metal segment is anticipated to maintain its lead during the forecast period and is expected to expand at the highest CAGR during the forecast period. Based on material, the industry has been segmented further into polymer, metal, and ceramic.

Component Insight

The hardware segment led the market and accounted for more than 63% share of the global revenue in 2023. The hardware segment has benefitted significantly from the growing necessity of rapid prototyping and advanced manufacturing practices. The growth of the hardware segment is primarily attributed to various factors such as rapid industrialization, increasing penetration of consumer electronic products, developing civil infrastructure, rapid urbanization, and optimized labor costs.

Regional Insight

North America led the market and accounted for more than 33% share of the global revenue in 2023. This can be attributed to the extensive adoption of additive manufacturing in the region. North American countries, such as the U.S. and Canada, have been among the prominent and early adopters of these technologies in various manufacturing processes. Europe happens to be the largest region in terms of its geographical footprint. It is home to several additive manufacturing industry players with strong technical expertise in additive manufacturing processes. Hence, the European market emerged as the second-largest regional market in 2023.

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

• The global accelerated processing unit market size was estimated at USD 13.85 billion in 2023 and is projected to grow at a CAGR of 17.5% from 2024 to 2030.

• The global centralized refrigeration systems market size was estimated at USD 29.87 billion in 2023 and is projected to grow at a CAGR of 5.0% from 2024 to 2030.

Key Companies & Market Share Insights

Some of the key players operating in the market include 3D Systems, Inc. and Materialise among others.

• 3D Systems, Inc. is the U.S.-based technology company. The company is involved in the development of Desktop 3D printing products and services such as 3D printers, materials, software, 3D scanners and virtual surgical simulators and haptic design tools. Additionally, the company serves its customers with 3D solutions to manufacture and design complex and unique parts, produce parts locally to reduce the lead time, and eliminate expensive tooling, among others. The company caters to numerous industries and verticals such as aerospace & defense, automotive, healthcare, educational, durable goods, and entertainment.

• Materialise is a Belgium-based technology company operating in the additive manufacturing industry. The company is actively involved in the field of Desktop 3D printing to develop a broad range of software solutions, Desktop 3D printing services, and engineering. The company primarily caters to the industries such as healthcare, aerospace, automotive, consumer goods, and art & design.

Key 3D Printing Companies:

• 3D Systems, Inc.

• 3DCeram

• Arcam AB

• Autodesk, Inc.

• Canon, Inc.

• Dassault Systemes

• EnvisionTec, Inc.

• EOS (Electro Optical Systems) GmbH

• ExOne

• GE Additive

• HP Inc.

• madeinspace.us

3D Printing Market Segmentation

Grand View Research has segmented the global 3D printing market based on component, printer type, technology, software, application, vertical, material, and region:

3D Printing Component Outlook (Revenue, USD Million, 2017 - 2030)

• Hardware

• Software

• Services

3D Printing Printer Type Outlook (Revenue, USD Million, 2017 - 2030)

• Desktop 3D Printer

• Industrial 3D Printer

3D Printing Technology Outlook (Revenue, USD Million, 2017 - 2030)

• Stereolithography

• Fuse Deposition Modelling

• Selective Laser Sintering

• Direct Metal Laser Sintering

• Polyjet Printing

• Inkjet printing

• Electron Beam Melting

• Laser Metal Deposition

• Digital Light Processing

• Laminated Object Manufacturing

• Others

3D Printing Software Outlook (Revenue, USD Million, 2017 - 2030)

• Design Software

• Inspection Software

• Printer Software

• Scanning Software

3D Printing Application Outlook (Revenue, USD Million, 2017 - 2030)

• Prototyping

• Tooling

• Functional Parts

3D Printing Vertical Outlook (Revenue, USD Million, 2017 - 2030)

• Industrial 3D Printing

o Automotive

o Aerospace & Defense

o Healthcare

o Consumer Electronics

o Power & Energy

o Others

• Desktop 3D Printing

o Educational Purpose

o Fashion & Jewelry

o Objects

o Dental

o Food

o Others

3D Printing Material Outlook (Revenue, USD Million, 2017 - 2030)

• Polymer

• Metal

• Ceramic

3D Printing Regional Outlook (Revenue, USD Million, 2017 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o U.K.

o Germany

o France

o Italy

o Spain

• Asia Pacific

o China

o Japan

o India

o South Korea

o Australia

o Singapore

• South America

o Brazil

• Middle East and Africa (MEA)

o KSA

o UAE

o South Africa

Order a free sample PDF of the 3d Printing Market Intelligence Study, published by Grand View Research.

Recent Developments

• In March 2023, 3D Systems, Inc. announced the launch of NextDent Cast and NextDent Base, two new printing materials, and NextDent LCD1, a printing platform. The materials are designed to enhance material properties, and the printing platform is an easy-to-use small-format printer. With these launches, the company aimed to aid its customers in accelerating additive manufacturing adoption.

• In November 2023, Autodesk Inc. announced the launch of Autodesk AI. This new technology is available in Autodesk products and is designed to provide customers with generative capabilities and intelligent assistance. With the launch of this new technology in Autodesk products, the company aimed to minimize errors by automating repetitive tasks and the needs of its customers.

• In February 2022, Dassault Systèmes has announced a strategic partnership with Cadence Design Systems, Inc. to provide integrated solutions for the development of high-performance electronic systems to enterprise customers in a variety of vertical markets, such as high tech, industrial equipment, and transportation and mobility, aerospace and defense, and healthcare.

#3d Printing Market#3d Printing Market size#3d Printing Market share#3d Printing Market analysis#3d Printing Industry

0 notes

Text

Durable and Accurate Prints with High-Quality 3D Printing Resin

Achieve flawless surfaces and fine detail with cutting-edge 3D Resin. Preferred across industries for its precision and consistent performance.

Modern manufacturing demands precision, durability, and innovation. Engineers, designers, and developers across the globe are constantly searching for the right material to bring digital designs into the physical world without compromising on quality. For industries looking to take their additive manufacturing capabilities to the next level, advanced 3D Printing resin has become an essential material. This resin offers the ideal combination of strength, flexibility, and resolution—making it indispensable for professional-grade 3D printing tasks.

At the core of this innovation lies Jyoticeramic , a brand known for engineering materials with exceptional performance in mind. The JYOCURE resin range is specifically developed for high-resolution stereolithography (SLA) and digital light processing (DLP) printers. This resin meets the needs of professionals who prioritize smooth finishes, detailed accuracy, and reliable outcomes in every print.

Resin printing has outpaced traditional methods in many sectors because of its ability to replicate even the smallest design elements. From functional parts to intricate concept models, 3D printing has revolutionized rapid prototyping. What sets apart high-grade resins is their post-cure durability and low warping properties—factors that are fully addressed in this modern printing material.

JYOCURE by jyoticeramic : Performance You Can Trust Engineered for industrial-grade performance, JYOCURE resin meets the demands of high-resolution 3D printing applications. It is designed to reduce shrinkage and eliminate layer misalignment during both the printing and curing processes. This resin adapts seamlessly across various sectors such as automotive, aerospace, dental, and consumer electronics, offering reliability and efficiency for professionals working in diverse printing environments.

Key Benefits of the Resin:

Excellent tensile strength ensures structural integrity

High-definition output on intricate geometries

Smooth, matte finish suitable for direct use

Reduced post-processing shrinkage

UV resistance and extended shelf life

Its robust formulation supports a wide range of printing systems, providing flexibility and consistent results.

Industrial Applications Driving Change The adaptability of this has made it a popular choice beyond conventional prototyping. Professionals use it to craft functional master molds, precise mechanical parts, and visually accurate mockups. Its role in medical modeling provides realistic anatomical structures beneficial for educational and surgical use.

With clear visual output and high thermal endurance, the resin is suitable for translucent enclosures and parts exposed to environmental stress. Its reliable mechanical properties make it ideal for rigorous product testing, both functional and aesthetic.

Professionals High-Performance Resin Automotive researchers benefit from this resin's ability to replicate detailed curves and fine textures directly from CAD models. This reduces development time and enhances prototype accuracy. Automotive parts printed with this material are visually polished and capable of fit and function testing, which improves team collaboration and speeds up design validation.

Engineers value this resin for consistent performance without requiring frequent recalibration. It enables complex design execution while maintaining fast iteration speeds. From mechanical assemblies to presentation-ready models, the resin supports innovation and efficiency in every stage of product development.

Design Studios Using 3D Resin for Client Mockups Design and marketing agencies rely on presentation-quality outputs. This resin accurately replicates engraved text, fine edges, and layered detail, helping creators deliver samples that match the original concept. It elevates customer interaction and supports faster decision-making.

Architects and consumer brands use this material to create scaled models that are not only visually compelling but also durable enough for handling. The tactile feedback enhances client satisfaction and makes concept validation smoother.

Educational Use and Innovation Hubs Academic institutions and tech labs are leveraging this advanced resin to support hands-on learning. It is widely used in fields ranging from biology to electronics. From visual teaching aids to circuit housing prototypes, the resin facilitates affordable and accessible digital fabrication.

Its compatibility with standard SLA systems makes it ideal for institutions aiming to improve their technical infrastructure without significant investments.

Applications Include:

Prototyping for automotive and aerospace industries

Dental and anatomical modeling

Jewelry and precision mold casting

Engineering and industrial design mockups

Educational and research-based fabrication

This versatile material transforms ideas into high-quality physical prototypes effortlessly.

Choose a trusted 3D Printing Resin for creating reliable prototypes and end-use parts. It empowers innovation through accuracy, speed, and material strength.

Visit: https://www.jyoticeramic.com/jyocure.php

Contact: +91 253 6918111

0 notes

Text

Installed the new direct drive extruder and hot end onto the 3D printer and successfully tested the extrusion of filament. Now to start a print!

0 notes